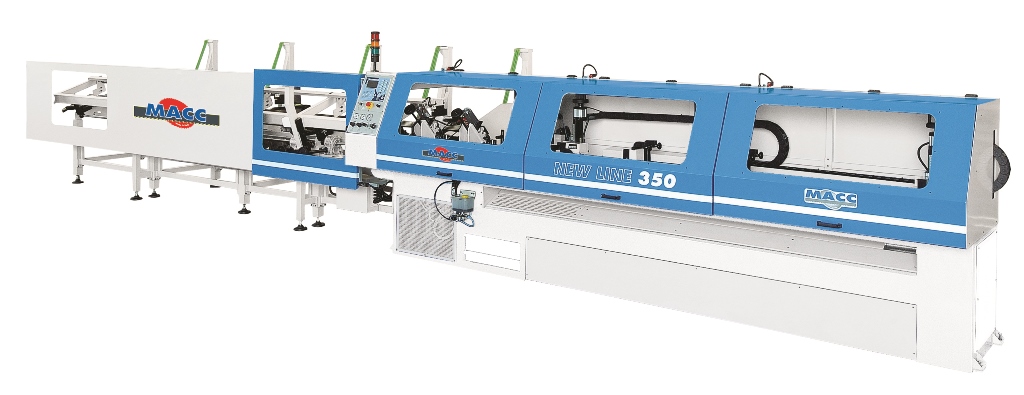

Description

TECHNICAL DATA AND STANDARD ACCESSORIES

- “CI” type automatic loader with inclined worktable designed for loading hollow or solid bars with round, square or rectangular section; rapid centralised adjustment of bar dimensions by means of just two handwheels, or “CF” type automatic bundle loader with anti-overlapping device for hollow or solid bar loading with round, square or rectangular section; rapid centralised adjustment of bar dimensions by means of just two handwheels.

- Bar feed unit supplied with rollers and driven by a gearmotor assisted by an inverter controlling rapid feed speed and the associated acceleration and deceleration ramps for bar feeding.

- Cutting head with 2-speed electric motor, motor amperometric absorption control, tempered and ground oil-bathed reducing gears, cutting head downstroke speed adjustment, blade double lubrication system (with emulsifiable oil or oil microlubrication).

- Bar locking with double vice.

- Pressure adjustment of bar feed rollers and double vice.

- Bar stop with digital instrument displaying bar cutting length, vertically movable stop retainer providing maximum accuracy of cutting repeatability.

- Automatic unloader provided with inclinable table for the selection of the side from which faced, cut or end-trimmed pieces are unloaded.

- New programming instrument with 5″ backlit graphic display for the management and optimisation of cutting parameters and settings.

ACCESSORIES ON REQUEST

- Extra bar stop adding a second cutting size option in sequence.

- Blade rotation inverter for speed variation according to the type of the material to be cut.

- Cutting-head with inclined linear movement, suitable for cutting square and rectangular pipes, with an entry into the bar which reduce at the minimum the frazes

- Inclined vice of 45°, for a better blocking of the piece to cut.